Norbar

閥門測試系統

產品簡介

閥門測試系統

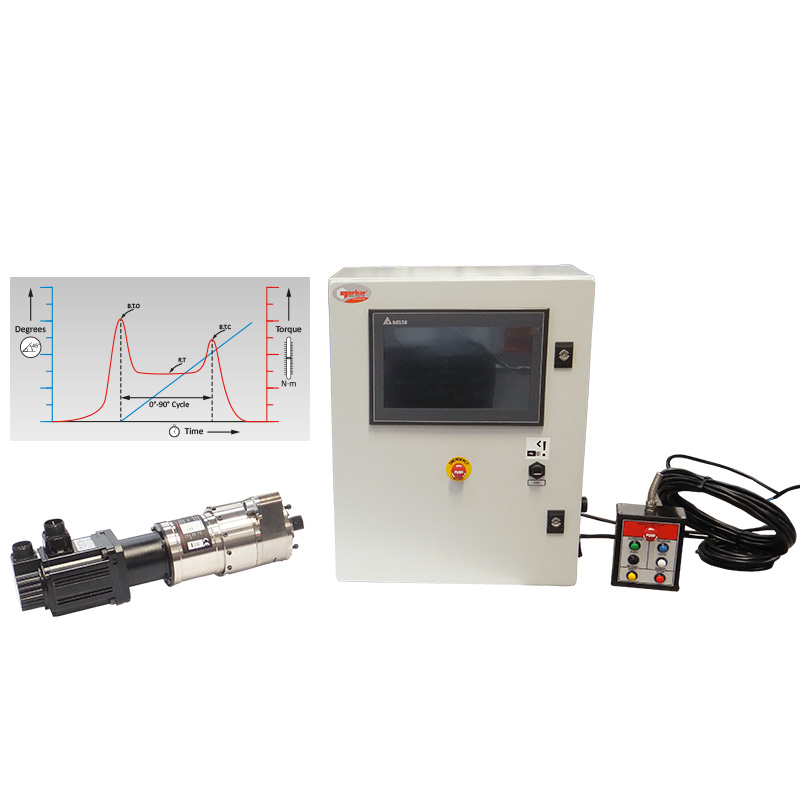

諾霸閥門測試系統設計通過扭力和/或角度測量方式來檢測和控制球閥及門閥的開關,並通過可選擇的相鄰開關來增加安全性。

使用以下任一方法施加扭力:

雙電磁閥控制任意諾霸PneuTorque®遠程系列工具正反向旋轉。

AC伺服電機控制正反向旋轉。

此系統可根據客戶預設的圈數進行循環。觸摸屏控制面板確保精確的扭力、角度及壓力監測。

閥門測試系統

閥門測試系統-功能介紹

- 典型應用包括測試球閥需要循環旋轉 0 - 90˚/ 90 - 0˚ ,並記錄扭力與角度數據。測試門閥/閘閥需開啟及關閉,並記錄扭力與角度/轉數數據。測試必須從測試室外部遠程控制,測試閥在測試室內加壓。

- 10"觸摸屏 HMI & PLC安裝在塗漆鋼質外殼中,室內/車間工位使用。

- 採集測試數據並以CSV格式輸出至外接U盤,包含時間及日期標記。

- 生成定制化測試報告及圖表。

- 通過RS232串行端口實時傳輸扭力及角度或扭矩及轉數數據流。

- 精密控制的低噪音伺服驅動。

- 操作氣動(通過電磁閥)或伺服驅動工具。

- 壓力、溫度及相鄰傳感器的專用輸入端口。

- 控制器可作為獨立組件升級現有閥門測試套組。

- 自動識別智慧傳感器。

- 正向/反向循環至用戶設定的循環數值,最高可達32,000刷。

- 急停按鈕及扭力過載限制功能。

- 諾霸久經考驗的PneuTorque工具配合扭力及角度傳感器滿足不同量程需求。

- 扭力範圍:100 - 300,000 N.m(應用中最大可提供500,000 N.m量程)

- 強大的無刷電機使用安靜,無需維護。

Valve Test System - Function Introduction

NORBAR'S VALVE TESTING SYSTEM HAS BEEN DESIGNED TO MONITOR AND CONTROL THE OPENING AND CLOSING OF BALL AND GATE VALVES BY MEANS OF TORQUE AND/OR ANGLE MEASUREMENT WITH OPTIONAL PROXIMITY SENSORS FOR ADDED SECURITY WHEN REQUIRED.

- The power to rotate the valve can either be supplied via an AC Electric or Pneumatic Motor. This is connected to One of Norbar's tried and tested epicyclic gearboxes.

- The size of gearbox is dependent of the torque required to operate the valve.

- The gearbox is fitted with an Annular Transducer which is used to measure the torque being applied to the valve,this transducer can be fitted with an optional angle encoder to allow for positional control.

- Norbar's systems allow differing levels of control from manual to fully automatic with cycling ability.

- The ability to monitor or record BTO and BTC as well as running torque is present across the range.

KEY FEATURES OF THE TOOL CONTROLLER

• 10” touchscreen HMI & PLC housed in painted steel enclosure for indoor / workshop use.

• Test data capture and output in CSV format onto external USB drive, time and date stamped.

• Generate customer test reports and produce graphs.

• Real time Torque & Angle or Torque & Turns Data streaming via RS-232 serial port.

• Precision controlled low noise AC servo drive.

• Operates pneumatic (via solenoid valves), or AC servo drive tools.

• Dedicated input ports for pressure, temperature and proximity sensors.

• Controller available as separate component to upgrade existing valve testing kits.

• Automatic recognition of Smart transducers.

• Forward / reverse cycling - user programmable number of cycles,variable up to 32,000 sweeps.

• Emergency stop button and torque overload limit function.

• Torque Range: 100 - 300,000 N·m (capacities up to 500,000 N·m available on application).

• Option of applying a brake to hold the angular position of the valve.

• High sample rate for positional data capture accuracy.